AI-Enhanced Dock Operations Dashboard-Logistics Facility Modernization

Client: Multi-site warehousing & logistics operations

Brief:

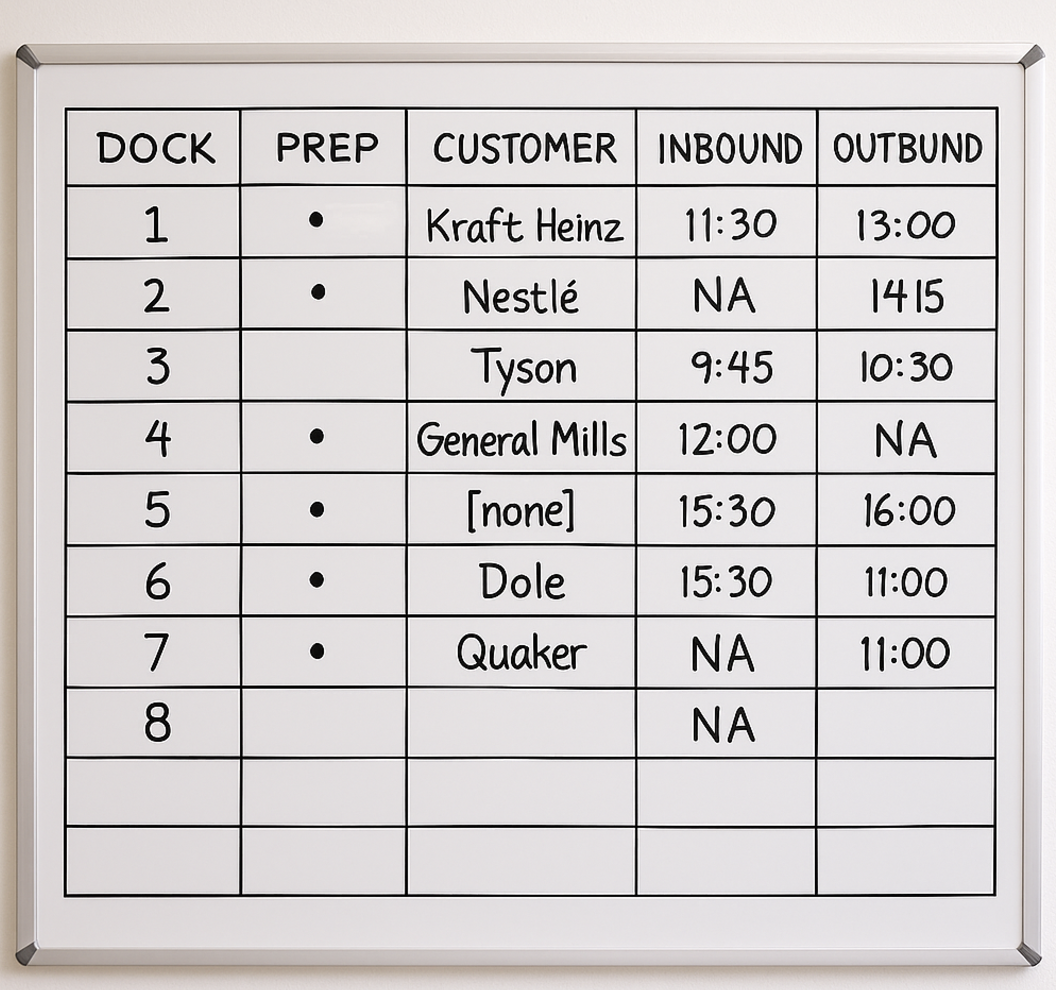

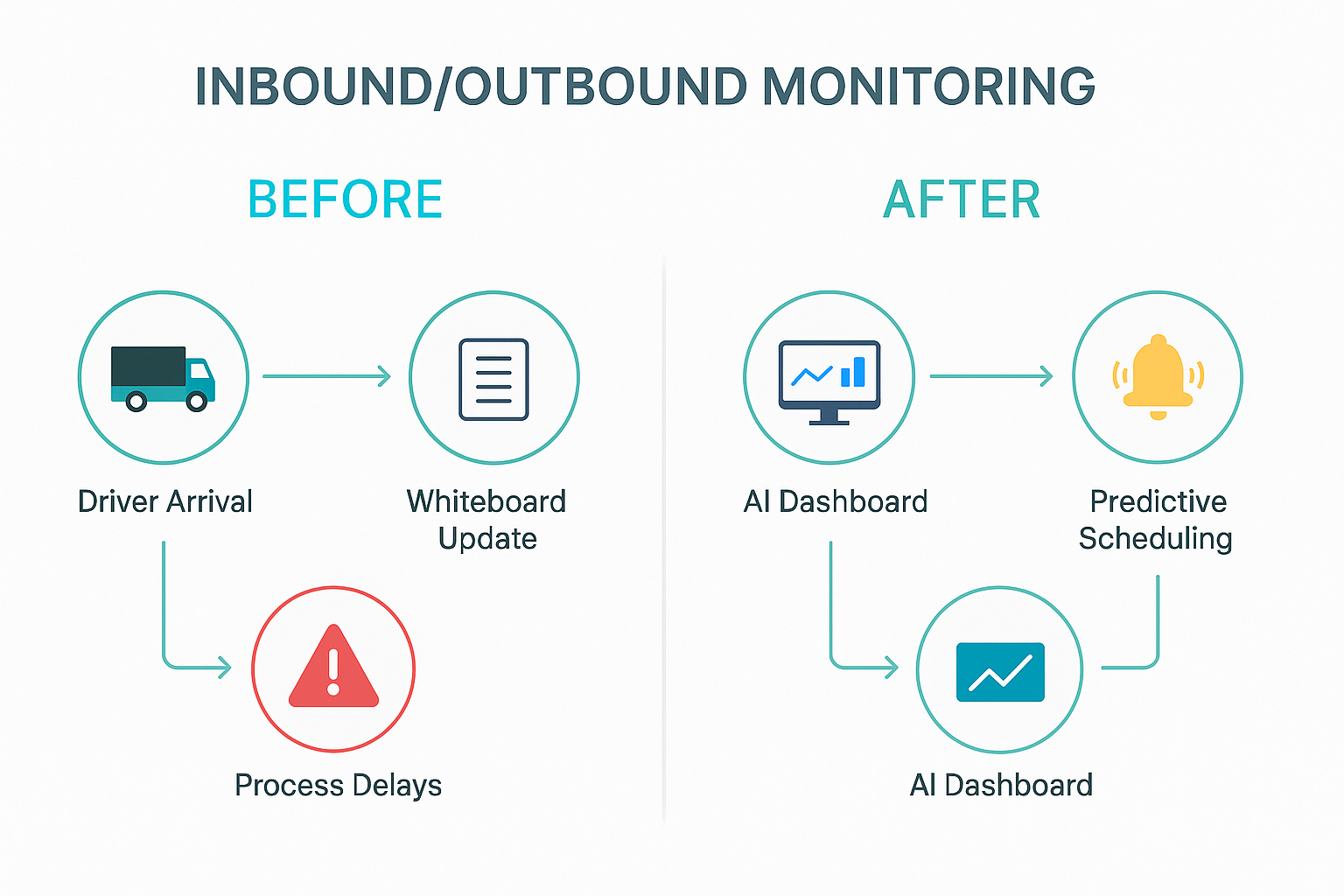

Replaced a manual whiteboard-based tracking process for inbound and outbound deliveries with an AI-enabled dashboard capable of live updates, predictive scheduling, and role-based visibility.

Product Goal: Improve dock utilization and throughput by replacing manual tracking with a real-time, AI-enabled operations dashboard supporting proactive decision-making.

Primary Users: Dock supervisors, yard managers, and operations coordinators overseeing inbound and outbound logistics.

Business Constraints: Multi-site variability, time-sensitive operations, limited tolerance for inaccurate predictions, and the need for role-based visibility across teams.

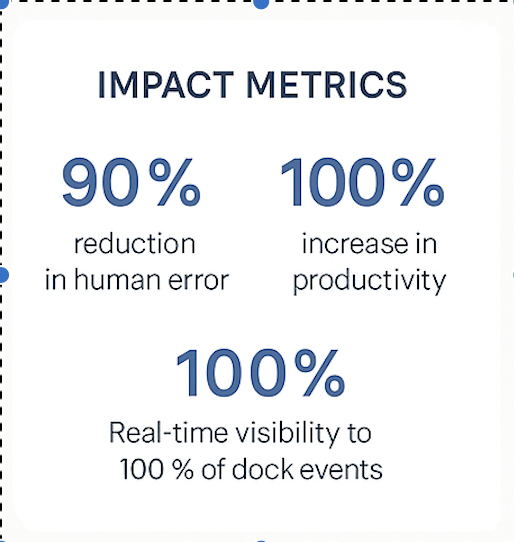

Success Metrics: Reduction in human error, improvement in dock utilization, on-time delivery performance, and user adoption across facilities.

Key Objectives:

Identify site-specific data needs for inbound/outbound monitoring.

Ensure real-time accuracy to reduce process delays and human error.

Incorporate predictive insights and alerts to optimize dock utilization.

Process & Responsibilities:

Conducted multi-site user interviews and usability testing to uncover role-specific needs and workflow bottlenecks.

Partnered with data science teams to integrate AI capabilities for ETA predictions and anomaly detection.

Designed and iterated a dashboard interface to improve usability, accessibility, and operational insight.

Facilitated adoption through training and change management strategies.

Key Product Decisions & Tradeoffs

Predictive Insights vs. Real-Time Reliability: Prioritized accurate real-time updates and anomaly detection before introducing more aggressive predictive scheduling to maintain operational trust.

Role-Based Visibility vs. Unified Views: Implemented role-based dashboards to reduce cognitive load and surface only actionable information for each operational role.

Scalability vs. Site Customization: Designed a flexible dashboard framework that supported site-specific workflows while maintaining consistent governance and data standards.

Build on Existing Systems vs. New Tooling: Integrated with existing warehouse data sources rather than introducing new infrastructure to reduce rollout risk and accelerate adoption.

Outcome:

Eliminated manual whiteboard tracking, reducing human error by 90%.

Improved real-time decision-making with predictive AI-driven updates.

Increased operational productivity by 100% across tested facilities.